Joining Technology Laboratory

Our offer

Our offer

The eLab offers joining technology systems for the generation of materially bonded joints for electrical contacting and various small part applications.

Together with process experts from the Institute of Welding and Joining Technology at RWTH Aachen University, ISF for short, feasibility studies can be carried out on new products and materials, precision-fit processes developed and sample components or small batches joined. The existing facilities are also suitable for basic development work, such as the identification of influencing factors and robustness tests for specific applications or the setup and calibration of precisely fitting quality monitoring systems for inline process monitoring.

Your Contact

Your Contact

Eric Helfers, M. Sc.

eric.helfers@isf.rwth-aachen.de

Phone: +49 241 80 97235

Data

Data

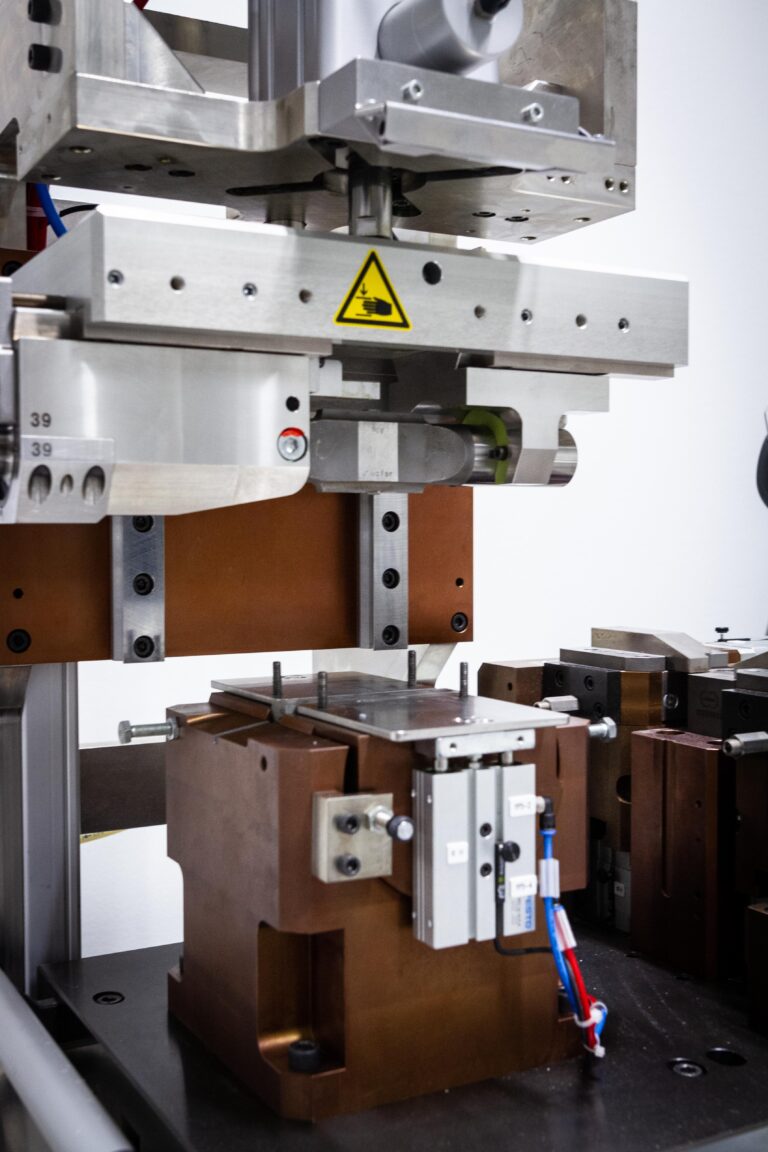

Ultrasonic metal welding system with dynamic process control

Ultrasonic metal welding system with dynamic process control

- 20 kHz/4 kW and 9 kW high-frequency generator, linear oscillator system, max. amplitude 35 µm

- Storage and visualization of process-relevant data at PC station

- Synchronisation with external high-speed measuring equipment (laser displacement sensors, eddy current sensors, video cameras) of the ISF

- Applications: welding of foils, sheets (0.01 to 3+ mm) and cables (up to 120 mm²) to sheets made of common conductor materials such as Al and Cu

- Plant poster (PDF)

Micro plasma welding system

Micro plasma welding system

- Welding current range: micro plasma from 0.06 to 50 A; WIG from 0.6 to 50 A

- Manual and automated micro plasma and TIG fine welding with/without pulses

- Applications: fine wire meshes and fittings, foils (from 0.01 mm)

- Plant poster (PDF)

Micro electron beam welding system

Micro electron beam welding system

- 60 kV/2 kW electron generator, image of the workpiece via REM mode

- Complex welding sequences programmable, teach-in function

- Applications: surface structuring, homogeneous/heterogeneous fine and micro welding seams; component structures from the fields of precision engineering, electrical engineering, etc.

- As a research institute, the ISF also has various systems for resistance, laser beam, arc and friction stir welding. Aside from the study of the joining process itself base materials and joints can be characterized comprehensively and assessed.

- Plant poster (PDF)

Examples of our research expertise

Examples of our research expertise

Metal Ultrasonic Welding Machine

- Development and validation of process strategies for connections with large conductor cross sections

- Analysis of various machine-, workpiece- and environment-related parameters on the welding process and its reproducibility

- Material-locking connections for electrotechnical applications

- Generation and optimization of mixed compounds

- Verification of process-related binding mechanisms

- Ageing behaviour and quality determination of various welded joints

- Design of inline systems for process monitoring

- Specification of process influencing variables and tolerance fields

- Visualization of the connection formation

Micro electron beam welding machine

- Parameter development for demanding small parts applications

- Surface structuring, also for medical applications

Micro plasma welding system

- Joining with low energy input

- Reduction of surface influences without post-treatment

Our technology partners

Our technology partners

https://www.isf.rwth-aachen.de/cms/~jbxx/isf/?lidx=1

Schunk Sonosystems GmbH

https://www.schunk-sonosystems.com/en/

http://www.oerlikon-welding.com

http://www.focus-e-welding.com

Funding Agencies

Funding Agencies