Electric Motor Testing Center

Our offer

Our offer

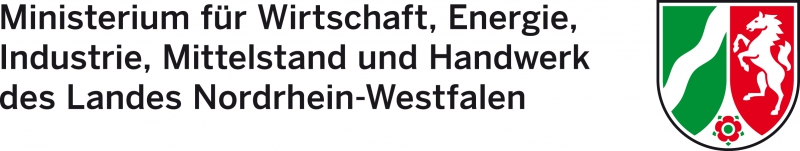

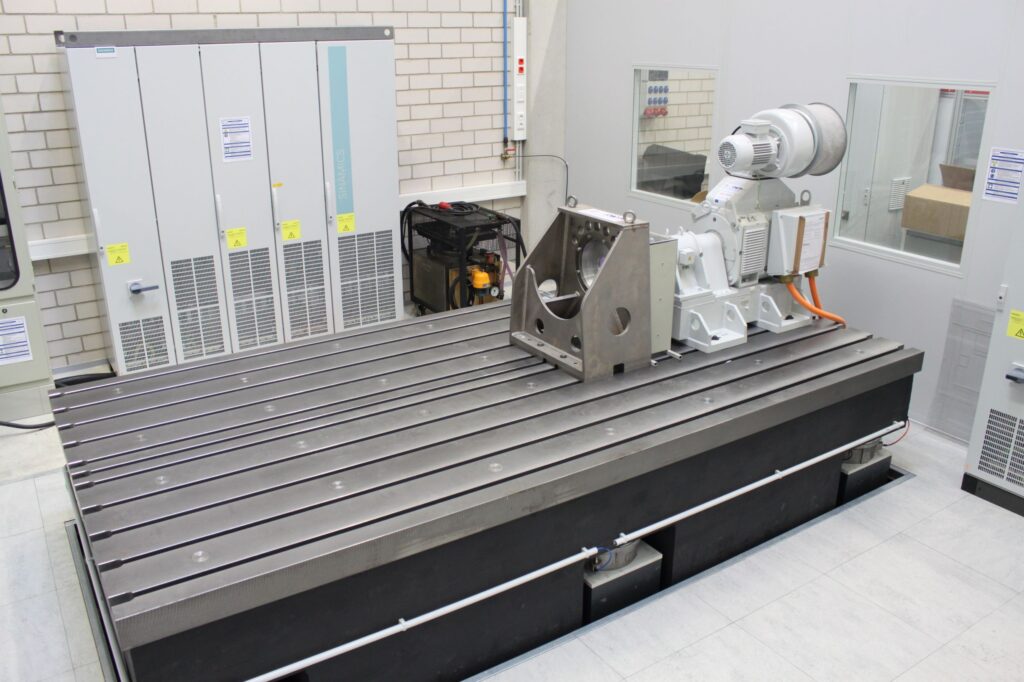

The test centre for electric motors makes it possible to carry out extensive analyses of electric drives. The test stand includes all components necessary for a measurement. These include the load machine, a vibration-decoupled machine bed and measurement technology for recording mechanical and electrical measured variables. The range of applications extends from efficiency measurements and load and demagnetisation tests to thermal validation and structure-borne sound measurements. In addition, the measurements for an ECE-R85 certification can be carried out for an approval of the motors as a drive in motor vehicles. The planning and set-up of the test object is guaranteed by experienced expert personnel. The examinations are accompanied by a measurement engineer who operates and monitors the test bench (plant poster; PDF)..

Your Contact

Your Contact

Data

Data

Load machine data

Load machine data

- Rated power: 140 kW

- Peak power: 175 kW

- Rated speed: 6081 min-1

- Maximum speed: 18.020 min-1

- Rated torque: 220 Nm

- Maximum torque: 275 Nm

- Final torque: 46 Nm

Battery simulator data

Battery simulator data

- Voltage range: 30 V to 800 V

- Peak power: 132 kW at 600 V

- Maximum continuous current: 200 A at 600 V

Examples of our research expertise

Examples of our research expertise

- Reduction of losses to maximize efficiency

- Detection of machine deformation

- Evaluation of environmental influences

- Thermal validation of the electric drive

- Improvement of the acoustic noise development

- Optimization of motor control

- Identification and reduction of ageing phenomena

To be able to fully cover topics in the field of electrical machines, four working groups are conducting research at the Institute for Electrical Machines (IEM).

Analysis and modeling

- Evaluation and modeling of the impact of fast-switching silicon carbide (SiC) power electronics on the lifetime of insulating material systems

- Development of novel insulating material systems

- Characterization and modeling of ferromagnetic and permanent magnetic materials under consideration of manufacturing influences as well as mechanical stresses

Design and diagnosis

- Design, analysis and optimization of electric drives for all applications

- Research into hybrid drive units

- Influence of rotor eccentricities and manufacturing tolerances on the operating behavior of electrical machines

- High speed electric machines

- Drive acoustics (NVH)

- Innovative cooling methods to maximize power density

- Interaction between e-drive oils and electric machine

Simulation and methods

- Development of numerical methods for the solution of electromagnetic field problems

- Methods of degree of freedom reduction of numerical models

- Integration of measured material effects into own software environment "pyMOOSE"

- Multiphysical system simulation of powertrains

Mechatronics and systems

- Sensorless control and predictive control systems

- Metrological characterization of electric drives and prototypes

- Operational management of wind turbines

- Investigation of operating strategies in hybrid systems with multiple energy sources

- Interaction between electric machine and the adjacent components, such as inverters

Funding Agencies

Funding Agencies